On 20th November, AKCOME celebrated a major breakthrough on HJT cell capacity! Full-scale production of domesticsingle-line 600MW 210 half-cut microcrystalline heterojunction cell at AKCOME Huzhou Base, which marks AKCOME 210 half-cut HJT cell into full-scale mass production stage.

This mass production of heterojunction cell takes the heterojunction structure as the breakthrough point. By introducing the microcrystalline process, it is conducive to improve short-circuit current, increase open-circuit voltage and improve the overall photoelectric conversion efficiency of heterojunction cell. At present, the efficiency of the first piece reaches 24.7%. It is expected that the efficiency of mass-production conversion directly exceeds 25% after the full-scale production, achieving the breakthrough of continuous cost reduction and improvement in heterojunction field.

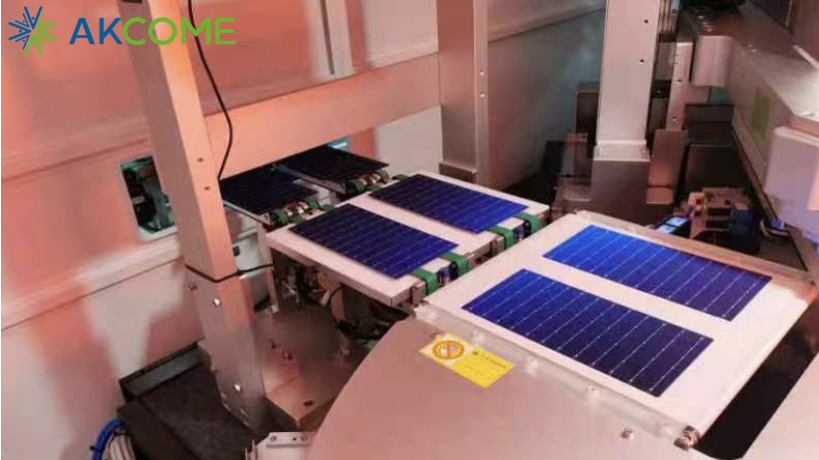

At present, the single-line capacity of the project has exceeded 600MW, and the equipment used is a fully domestically manufactured single-line 600MW large-scale energy production equipment. The production line is currently introducing 120μm wafers and 100μm wafers are being tested simultaneously. In terms of slurry cost reduction, the AKCOME’s original silver-free main grid technologyand silver-clad copper fine grid technology will be fully introduced, while the manufacturing cost will be reduced through lean management.

It is worth mentioning that in order to achieve the “digitalization” of the production and operation, AKCOME directly introduces the whole line MES management system into the production line, achieving point-to-point track of the semi-finished and finished wafers, and finally maximize the yield of the production line. At the same time, through comprehensive automatic statistics control and continuous optimization of the cost modules such as material consumption, electric energy consumption and labor attendance of production equipment, AKCOME Technology has made a positive contribution to the reduction of manufacturing costs and achieve intelligent manufacturing and lean manufacturing for heterojunction production.

With the conversion efficiency of PERC cell approaching the theoretical limit, the trend of photovoltaic industry towards N-type technology transformation is becoming more obvious. In this context, improving conversion efficiency and reducing LCOE has become the eternal theme of photovoltaic industry. The heterojunction technology features a simple process, ultra-low silicon consumption, high conversion efficiency, low attenuation, low temperature coefficient and many other advantages. Its industrial development process is accelerating and the industry technology continues to break through, which is expected to become the next generation of mainstream solar cell technology.

It is known that the conversion efficiency of heterojunction cell independently researched and developed by the peer enterprises recently reached 26.81%, breaking the highest record of the efficiency of silicon-based solar cells in the world, as well as being the first time in photovoltaic history that a Chinese solar technology company has created a world record for silicon cell efficiency. This not only fully demonstrates the technological strength of silicon solar cell manufacturing by China photovoltaic enterprises, but also strengthens the confidence and determination of AKCOME to continue to move forward on the heterojunction technology route.

Godziny Odpowiedzi: 8:00-17:00 w dni robocze

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Siedziba: pokój 901, budynek 1, nr 1818-2, Wenyi West Road, Yuhang Street, dystrykt Yuhang, miasto Hangzhou, prowincja Zhejiang